What is an Armorite Door?

According to a quick Google AI search, Armorite is :

a brand of exterior-grade, no-added formaldehyde (NAF) medium-density fiberboard (MDF) panel manufactured by Roseburg Forest Products. It's designed for various exterior applications, offering moisture, rot, and insect resistance, including termite protection. Armorite is also known for its machinability, paintability, and suitability for high-humidity environments.

Key features and uses of Armorite:

Moisture, rot, and insect resistance: Armorite is treated with a biocidal treatment process and contains zinc borate to prevent fungal decay, rot, and termite damage.

No added formaldehyde: It's made with a formaldehyde-free resin.

Exterior applications: Armorite is suitable for a wide range of exterior projects, including exterior cabinetry, countertops, signage, garage doors, shutters, raised panels, and non-structural paint-grade millwork.

Machinability and paintability: It is designed for easy machining, nailing, and finishing, and is also paintable.

High-humidity environments: Armorite is well-suited for use in high-humidity climates and above-ground exterior applications.

Sustainable: It is manufactured with Western softwoods and is available with third-party certified 90.5% pre-consumer recycled content.

Exterior Trim: Armorite also comes in an exterior trim version, designed for builders and contractors, with a factory-applied primer and reversible smooth and woodgrain textures.

Armorite is a very moisture resistant variation of MDF. This is very important for cabinets, especially in the kitchen and bathrooms. Your standard MDF would swell with water exposure. Armorite is much more resilient.

Armorite’s ability to be machined (cut on a CNC router) and it’s water resistant qualities make it a great option for cabinet doors, because it saves so much labor, and for you as the buyer, cost. Once it is painted, it is hard to tell it apart from a standard wooden framed door.

The cost of an Armorite door is about 60% of a wooden framed door on our cabinets.

We believe in this product. My father, who built cabinets for 40 years, refaced his kitchen with these about 7 years ago. They look great to this day. You would never know they weren’t a wooden door.

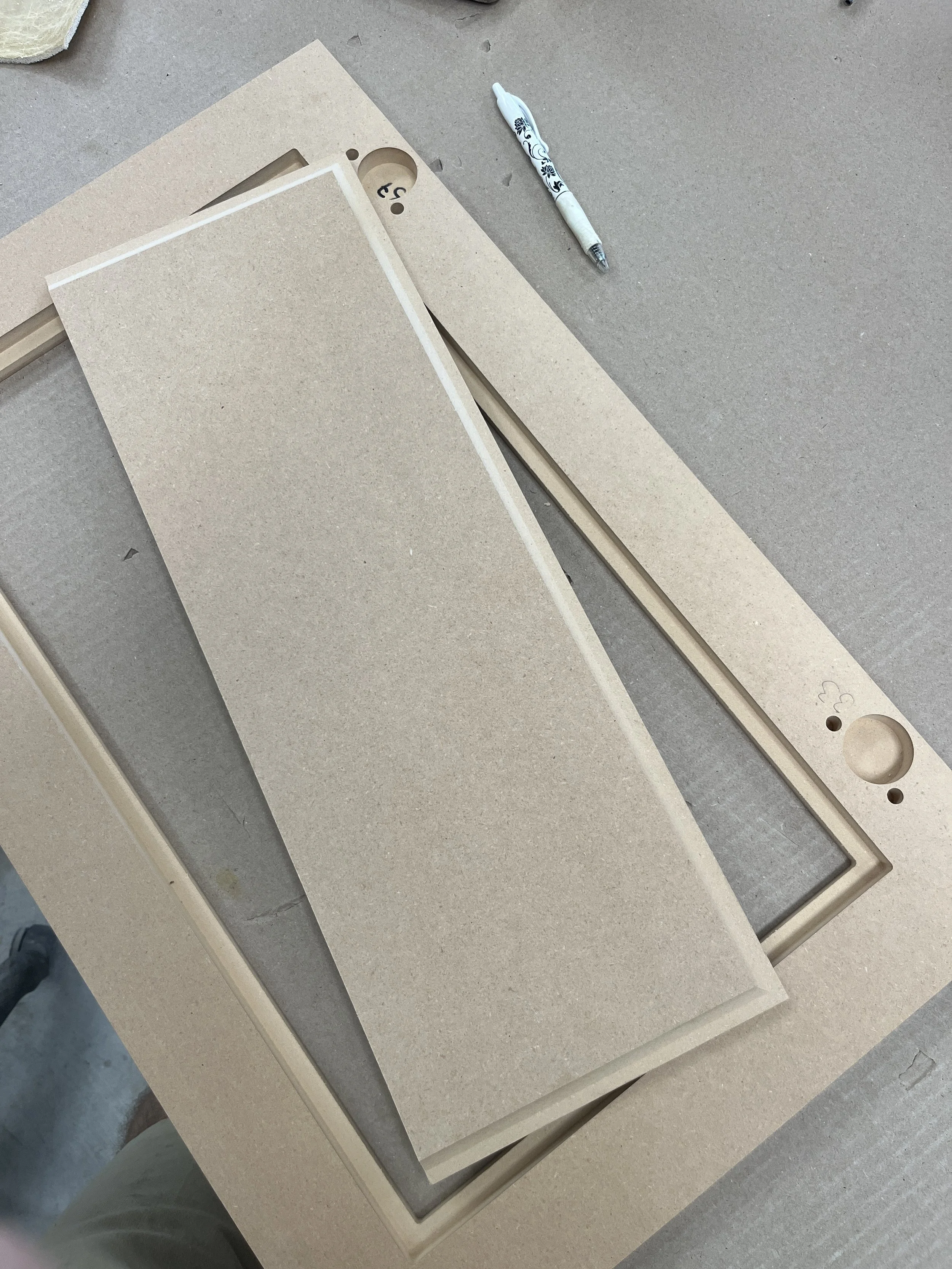

Below are a few pictures of what an armorite door looks like without paint. The panel is made up of 3/8” Armorite and the frame is made up of a single piece of 3/4” armorite. One benefit to the frame being a single piece is that it has no seams. On wooden doors, there is always the possibility of the painted seam showing wear over time by revealing a small crack.

To assemble these doors, we simply glue the panel in the back of the door and nail it with 21 gauge pin nails. Once primed, we caulk that seem to give it a finished look. Once the door is finished, it is very solid. To demonstrate the durability of the joint between the panel and the frame, I tried knocking the panel out of the door frame with my hammer. The bond was so strong that I ended up knocking a hole in the door panel with not much noticeable breakage in the bond.